Hot Rod Magazine

Maximus on the cover of Hot Rod Magazine, April 2020.

It Took Nelson Racing Engines Nearly Eight Years To Build This Twin-Turbo 1968 Charger. When You Read The Story, You Will Understand Why.

This is Maximus. It's an eight-year, 16,000-man-hour, bare-metal homage to one of the greatest muscle cars ever created. This isn't some garage-built restomod or a bolt-on showcase. Instead, Maximus is a one-off, coachbuilt masterpiece that has been crafted from forged steel, desire, and the will to create the most influential and technologically advanced 1968 Dodge Charger the world has ever seen.

Owner Scott Spock knew he wanted a Charger since he was a little kid. A neighbor had a 1968 Charger, and Scott says it was the most incredible machine he had ever seen. "One day, I'm going to have the most incredible '68 Charger ever built. I just needed to figure out how to do that."

"He was the only guy that you'd see actually driving the cars and showing real dyno numbers, so I scheduled some time and went to see him," - Scott Spock

Things got rolling once he came across Tom Nelson. "He was the only guy that you'd see actually driving the cars and showing real dyno numbers, so I scheduled some time and went to see him," Scott says. During their conversations, a plan started to form, and the search for a donor car began. Found in Southern California, Scott admits that the donor car was a complete disaster when purchased initially, but it came with a part that's almost unobtainable in the '68 Charger world—a perfect grille. While he knows he overpaid for the car, he also noted that it was precisely what was needed to get the process rolling, and so a ragged, old Charger was delivered to Nelson Racing Engines in Chatsworth, California. Once at the shop, they began taking stock of what they had to work with, and the mad-scientist phase of the project started.

Change Of Plans

Tom Nelson picks the story up from here, saying, "Originally, it was going to be more of a Pro Street Charger. We always planned it as a twin-turbo Hemi, but for the most part, it was more or less going to be a bolt-together car. We had a plan and started sandblasting and cutting the car apart, then we put it on the frame table—this is where the biggest change in Maximus came. We had initially planned to fit a 345/35-series rear tire, but when we put the tire under the car Scott didn't seem too excited." Scott wanted wider tires.

In case you were wondering, a 345/30-series tire is a lot of rubber. For reference, a 2017 Dodge Viper ACR runs a 355/30-series rear, a 2019 Porsche GT3 RS has a 325/30, and even a new Lamborghini Aventador wears a 355/25. Implying that a 345/35-series looks weak, well, that's just looney. Then again, it also gives you an idea of where Scott's head was.

"When Tom put the tires on it, I just thought, 'Man, it's not right. It's not what I was thinking.' I told Tom that I wanted to get a bigger footprint out back because I knew we'd be making at least 1,500 bhp, but he said, 'That would be great, but we just don't have room.' So I just said, 'Well, what if we widened it?'" Scott says.

At this point, Scott began to worry, as the one thing he was adamant about was that the car had to be fully recognized as a 1968 Dodge Charger. Tom came up with the idea that would not only enhance that beautiful Coke-bottle shape but also allow it to run some mammoth rubber out back. The plan was to begin the widening process at the doors, then angle it back for a total of a 3-inch width increase on each side. After some calculations and mockups, a final decision was made, resulting in a one-off set of Bonspeed wheels. The rear wheels were 20x18 with a set of 30x20x18 Mickey Thompson tires; the 9x11 front wheels wore a more modest 275/45-series Pirelli P Zero. Did the widening process add a few extra years to the journey? It sure did, but what a difference it made.

At this point, we're significantly oversimplifying how Tom and the guys at NRE widened the car, because if we went into detail, it would fill a book. The process was excruciatingly time consuming and resulted in the Charger becoming a full-on coachbuilding experience. As Tom describes it, "If you put a 30-inch-tall tire on and try to get the car sitting low, the rear tires would be sitting on the rear framerails. If you had to make it fit without modifying it, the thing would look like a 4x4. We actually cut away the entire back end of the car and handmade the rear framerails and the entire rear suspension. It's completely our own design, as is the front, which uses adjustable coilovers with a custom rack-and-pinion with modern geometry. The rearend is a big-tube 9-inch that's completely reinforced, has 35-spline street axles, a 1350 yoke, and a Nodular center section. Everything was done in solid works, then we would water-jet the parts. It was all done in-house."

All The Power

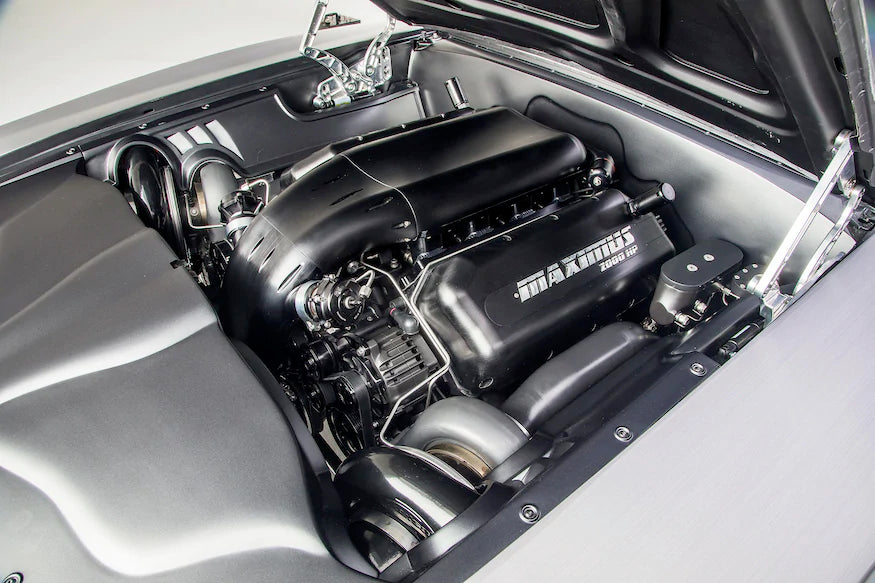

From the beginning, there was only one engine being considered: the Gen II Hemi. Several iterations were discussed, and eventually a 572-cubic-inch Hemi found its way into the engine compartment. Considering this is Nelson Racing Engines, you might assume it's something more exotic than your run-of-the-mill 426 Hemi, and you would be correct. What you're seeing here is a 572-cubic-inch Hemi (that's 9.4L) that utilizes twin NRE 88mm turbochargers, twin intercoolers, and a computer-controlled dual-injection system that switches automatically between 91 and 116 octane fuel when the octane threshold is reached. In the trunk is a dual-reservoir fuel tank that was CNC'd from a solid 2,000-lb block of aluminum. The tank features internal baffling, rollover vents, as well as all the plumbing. It is a sculpted work of art. The verified horsepower and torque numbers on Maximus are also mind-bending: 2,253 hp at 6,200 rpm, and 1,927 lb-ft of torque at 6,000 rpm—and this is at just 25 psi of boost. Tom claims that if the boost pressure is increased to 45, power output would be just shy of 3,000 hp, making it the most potent Street Hemi that NRE has ever produced.

All this power is going to the rear wheels via a highly modified Tranzilla TR6060 six-speed manual transmission from Rockland Standard Gear Inc, and for extra insurance, a built-in GPS-based traction control system is employed to keep that power in check, as well as a five-mode horsepower/boost controller switch that lets the driver toggle between 1,000 and 2,000 hp.

Inside, every surface, switch, button, vent, relay, and trim panel is a bespoke piece. To give the briefest of examples, a stock Chrysler stereo from 1968 now sits on a rotating James Bond style panel that electronically flips over to expose a modern touchscreen.

The steering wheel, which at first appears stock, is actually a billet piece covered in hand-stitched Italian leather with hidden buttons on the rear of the spokes that control many of the car's functions. Then there's the center console, with its rotary boost knob and toggle switches. It looks so good, it'll make you wonder why all consoles aren't designed this way. ... continue on HotRod.com

Mike Musto - Author

John McGann - Author

Jorge Nunez - Photographer

Mar 27, 2020

Read More on HotRod.com

Be the first to comment